- Home Page

- Company Profile

-

Our Products

- HSS M2 TAPER SHANK TWIST DRILLS

- HSS STRAIGHT SHANK DRILLS - JOBBER SERIES

- HSS Hand Reamers - Straight Flutes

- HSS (M2) 4 Flute End Mill Parallel Shank

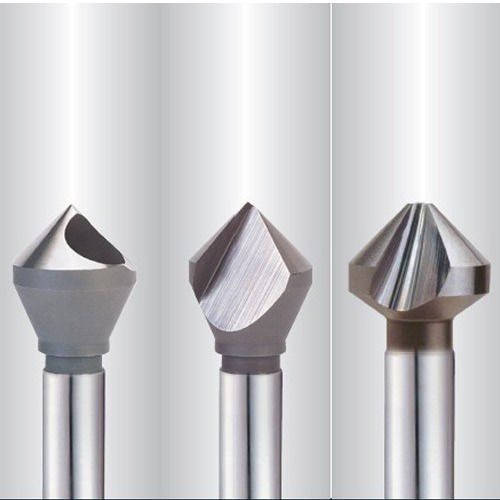

- Counter Sinks

- Counterbore Drills

- Ground Carbide Bar

- YG1 Reamer

- Emkay Taps

- YG1 Milling Tools

- YG1 Drills

- YG1 Threading Tools

- Saw Blades

- others R. S. Tools

- YG-1 all products

- Contact Us

HSS Countersink Cutter

500.00 - 5000.00 INR/Piece

Product Details:

- Material High Speed Steel

- Cutter Type Countersink Cutter

- Machine Type Drill press, hand drill, CNC machine

- Usage For Drilling and Cutting

- Operate Method Manual or machine operated

- Cutting Force Low operating force required

- Tool Type Countersink Cutter

- Click to View more

X

HSS Countersink Cutter Price And Quantity

- 500 Piece

- 500.00 - 5000.00 INR/Piece

HSS Countersink Cutter Product Specifications

- Countersink Cutter

- High Speed Steel

- For Drilling and Cutting

- Drill press, hand drill, CNC machine

- 10 mm to 50 mm

- Multi-flute

- Silver and Grey

- Depends on diameter and application

- Sharp edges, precise cutting, durable, heat resistant

- Straight

- Manual or machine operated

- Countersink Cutter

- Low operating force required

- Suitable for deburring and chamfering

- Deburring, Chamfering

- HRC 60-65

- Rotary

- Up to 35 m/min

- High precision

- Standard and customized lengths available

- Uncoated

HSS Countersink Cutter Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 500 Piece Per Day

- 1 Days

- All India

Product Description

A countersink cutter is a tool used to create a conical-shaped recess in a material, typically metal or wood, to allow for the flush insertion of a screw or bolt. The cutter is designed with a pointed tip that is inserted into a pre-drilled hole and gradually widened to create the countersink.

Countersink cutters can be found in a variety of sizes and shapes to accommodate different screw or bolt sizes and material thicknesses. They can be used with handheld drills or drill presses and are commonly used in woodworking, metalworking, and construction applications. Countersinking can help prevent screws or bolts from sticking out and causing potential hazards or creating an uneven surface.

Versatile Application Across Materials

Designed for professional and industrial use, the HSS Countersink Cutter excels in deburring and chamfering tasks on metal, wood, or plastic. It maintains consistent performance whether operated manually or with machines such as drill presses, hand drills, or CNC equipment, making it a reliable choice for diverse manufacturing environments.

Precision Engineering for Cleaner Results

Engineered with sharp cutting edges and multi-flute options (3 or 6), the cutter delivers high precision and clean countersinks. Selectable point angles and accurate blade sizing provide control over finish quality, reducing surface defects and ensuring smoother assembly or finishing in your workpieces.

Durable Construction and High Heat Resistance

Manufactured from high-speed steel, the cutter withstands intensive use and elevated temperatures. Its hardness rating of HRC 60-65 and uncoated bright finish offer longevity, while the robust design allows for low operating force, minimizing operator fatigue and equipment wear over time.

FAQs of HSS Countersink Cutter:

Q: How can I choose the right number of flutes and point angle for my application?

A: Select the number of flutes (3 or 6) based on the desired surface finish and material type; more flutes generally provide smoother results. For point angle, consider the workpiece material: 82 is typical for metals, 90 for wood and plastics, while 60 or 120 serve specialized needs. Matching these specs to your material and application ensures optimal performance.Q: What materials can this HSS Countersink Cutter process effectively?

A: This countersink cutter is suitable for processing metal, wood, and plastic. Its high-speed steel construction and bright finish allow for efficient deburring and chamfering across these materials, providing clean and precise finishes regardless of the substrate.Q: When should I use a manual operation versus machine operation for this cutter?

A: Manual operation is ideal for small volume work or detailed tasks, especially when using hand drills. Machine operationincluding drill presses and CNC machinesis recommended for larger quantities or where consistent, precise results are required, increasing productivity and uniformity in industrial settings.Q: Where can this countersink cutter be installed and used?

A: The HSS Countersink Cutter can be fitted into a variety of equipment such as hand drills, drill presses, or CNC machines. Its straight or round shank compatibility and range of diameters (10 mm to 50 mm) allow for versatile installation across different workstations and applications.Q: What is the process for deburring and chamfering with this cutter?

A: Mount the cutter in the desired equipment, set appropriate speed (up to 35 m/min), and select the correct diameter and point angle. Operate by engaging the rotary motion, applying gentle pressure; the sharp edges efficiently remove burrs and create chamfers, resulting in a smooth, clean hole or edge.Q: What are the main benefits of using this countersink cutter?

A: Key benefits include high cutting precision, durability due to HRC 60-65 hardness, heat resistance, low operating force, and universal applicability on multiple materials. The tool produces sharp, clean edges, reduces rework, and is available in customizable sizes for various industrial requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email