- Home Page

- Company Profile

-

Our Products

- HSS M2 TAPER SHANK TWIST DRILLS

- HSS STRAIGHT SHANK DRILLS - JOBBER SERIES

- HSS Hand Reamers - Straight Flutes

- HSS (M2) 4 Flute End Mill Parallel Shank

- Counter Sinks

- Counterbore Drills

- Ground Carbide Bar

- YG1 Reamer

- Emkay Taps

- YG1 Milling Tools

- YG1 Drills

- YG1 Threading Tools

- Saw Blades

- others R. S. Tools

- YG-1 all products

- Contact Us

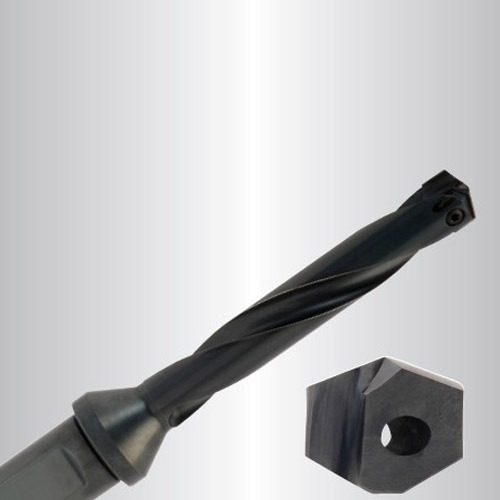

NC Spotting Drills

2000.00 - 10000.00 INR/Piece

Product Details:

- Shape Straight

- Usage For Cutting and Drilling Purpose

- Material Others

- Color Silver

- Click to View more

X

NC Spotting Drills Price And Quantity

- 5 Piece

- 2000.00 - 10000.00 INR/Piece

NC Spotting Drills Product Specifications

- Silver

- Straight

- Others

- For Cutting and Drilling Purpose

NC Spotting Drills Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 500 Piece Per Day

- 1 Days

- All India

Product Description

NC spotting drills are cutting tools used in metalworking applications to create precise holes in a workpiece. They are designed to accurately locate the center of a hole before drilling, which helps to improve accuracy and reduce the risk of errors.

NC spotting drills are typically used in CNC (computer numerical control) machines, where the drilling process is automated and highly precise. They can also be used with manual drilling machines, and proper cutting fluid should be used to reduce friction and heat buildup during the drilling process.

NC spotting drills have a pointed tip and a short flute length, which helps to improve accuracy and prevent the drill from wandering during the drilling process. They are available in different sizes and materials to accommodate a wide range of applications.

One of the main advantages of using NC spotting drills is their ability to accurately locate the center of a hole, which helps to improve the overall precision of the drilling process. They can also help to reduce the risk of errors and improve efficiency, as they can be used to quickly locate the center of multiple holes in a workpiece.

Proper maintenance of NC spotting drills is important to ensure optimal performance and longevity. Regular cleaning and inspection of the drills, along with proper storage and handling, can help prevent damage and extend their useful life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email